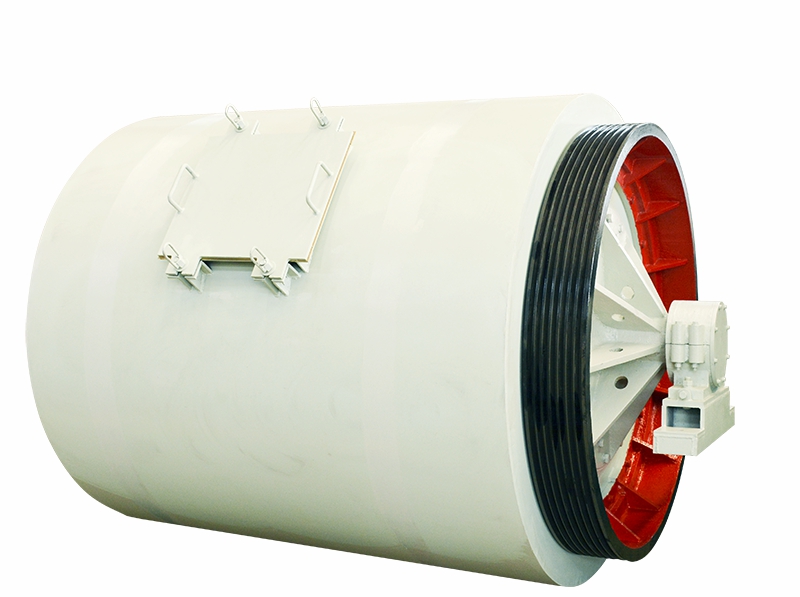

Ceramic Ball Mill Machine

【What’s the Ceramic ball mill machine?】The ceramic-type batch ball mill is a small non-continuously produced ball mill. The utility model has the advantages of simple structure, convenient operation, less auxiliary equipment, and high-definition products can be obtained at one time. The fineness of the product is generally 800 mesh or more, even 2000 to 3000 mesh, and the fineness is easy to control. The use of ceramic lining, high-aluminum ceramic grinding media, can reduce energy consumption and avoid iron pollution. It is applied to small production lines with high product fineness and can not be polluted by iron.

【Feature of Ceramic ball mill machine】

1. The grinding fineness can be adjusted freely according to the grinding time.

2. The lining plate is detachable. Users can change different types of liners according to production needs.

3. The motor can realize an automatic voltage soft start to reduce starting current.

【Ceramic ball mill Manufacture】As a Ceramic ball mill manufacturer, we could provide the worry free after-sales guarantee when purchasing equipment in our company. You have a specially assigned person to be responsible for every step of production, and you have a specially assigned person to solve the late faults in time, so as to ensure the smooth and high-yield progress of your production.

Ceramic Ball Mill Structure

【Ceramic Ball Mill Parts】The ceramic ball mill is a horizontal cylinder ball mill. It is composed of the feeding part, discharging part, rotary part, transmission part (reducer, transmission gear, motor, and electrical control device), lining plate, grinding medium, and other components. The quill shaft is made of steel casting and the lining plate is detachable.

【Working Principle of Ceramic ball mill】The motor drives the ceramic ball mill cylinder to rotate through a reducer. When the cylinder rotates, raw materials and grinding mediums inside are thrown up and then dropped by the action of friction and centrifugal force. In this process, they produce impact force on each other to complete the grinding of materials. After that, the ground material is discharged out of the ball mill through the discharge port and then enters a spiral classifier for screening. The large particles will be sent back to the ball mill for further grinding.

Ceramic Ball Mill Technical Parameter

Model | Capacity(tons/time) | Cylinder Rotation Speed(r/min) | Power(kw) | Lining Plate Type |

600×700 | 0.05 | 50 | 2.2 | ceramic, silica, rubber, metal |

800×600 | 0.075 | 42 | 3 | ceramic, silica, rubber, metal |

900×1200 | 0.2 | 38.5 | 5.5 | ceramic, silica, rubber, metal |

1300×1500 | 0.5 | 33 | 7.5 | ceramic, silica, rubber, metal |

1500×1800 | 1.2 | 28.5 | 11 | ceramic, silica, rubber, metal |

1800×2000 | 1.5 | 24 | 15 | ceramic, silica, rubber, metal |

2600×2800 | 5 | 16.5 | 37 | ceramic, silica, rubber, metal |

3000×3800 | 10 | 14.5 | 57.2 | ceramic, silica, rubber, metal |

3200×4600 | 15 | 13.5 | 75 | ceramic, silica, rubber, metal |

Send us a message

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.