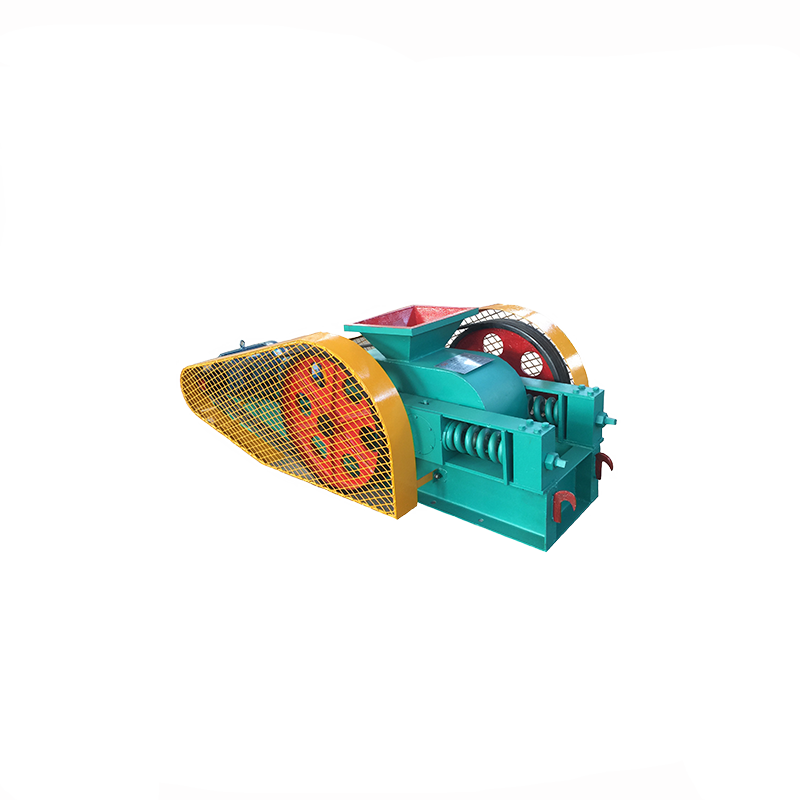

Double Roller Crusher

【What’s the Roller Crusher?】The Double Roller Crusher, also known as roll crusher, toothed roll crusher, is suitable for fine crush the medium hardness rock with compressive strength ≤160MPa, such as ore, rock, coke, coal, clinker, ceramic raw materials, slag, refractory materials, and chemical materials. According to the number of rolls, the roll crushers can be divided into single roll crusher, double roll crusher or, four roll crusher. Double roll crusher is the most used type. We produce industrial roller crushers and laboratory uses small roll crusher.

【Feature of Roller Crusher】The input size is large and the output size can be adjusted. It can resist pressure strength is less than 160MPa. Especially in the coal industry, to use for fragmentation of raw coal, as long as removing iron, impurity, without gangue removal, it can be directly to broken, the granularity of output size can simplify the coal preparation process, reduce the investment and production cost.

【Roller Crusher Factory】ZJJX, one Chinese rock crusher manufacturer, supply roll crushers global, we establish a wear parts supply system to meet customer’s parts replacement needs are met and reduce the downtime.

Factory price, fast delivery, one year warranty, on-site installation, support roll crusher design.

Roller Crusher Structure

【Roller Crusher Parts】Bearing box, roll shell, bearing housing, adjusting rod, motor, carrier, fixed roller, movable roller and safety spring, etc.

【Working Principle of Double Roller Crusher】The roller of the roller crusher is supported by the spring pressure. Under normal working conditions, the spring force is sufficient to overcome the crushing force of the crushed material. By changing the number of spacers between the frame and the movable bearing, the width of the discharge port between the two rolls can be adjusted to adjust the grain size.

When there is a material that cannot be broken into the crushing chamber, the spring is compressed, and the movable roller is retracted to increase the discharge opening. After the material is discharged, the movable roller is reset under the spring pressure.

Roller Crusher Technical Parameter

Model | 2PG0425 | 2PG0640 | 2PG0740 | 2PG0850 | 2PG1060 | 2PG1260 | 2PG1560 |

Roller diameter(mm) | Ф400 | Ф600 | Ф700 | Ф800 | Ф1000 | Ф1200 | Ф1500 |

Roller width(mm) | 250 | 400 | 400 | 500 | 600 | 600 | 600 |

Input Size(mm) | ≤25 | ≤25 | ≤25 | ≤25 | ≤30 | ≤30 | ≤30 |

Discharging Gate(mm) | 2-8 | 2-8 | 2-8 | 2-8 | 2-10 | 2-10 | 2-10 |

Processing capacity(t/h) | 5-10 | 10-20 | 15-30 | 20-40 | 30-50 | 40-70 | 60-110 |

Power Models | Y132M-6 | Y180L-6 | Y200L-4 | Y225M-4 | Y250M-4 | Y315M-6 | Y315L-6 |

Motor power(kw) | 5.5×2 | 15×2 | 30×2 | 45×2 | 55×2 | 75×2 | 110×2 |

Send us a message

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.