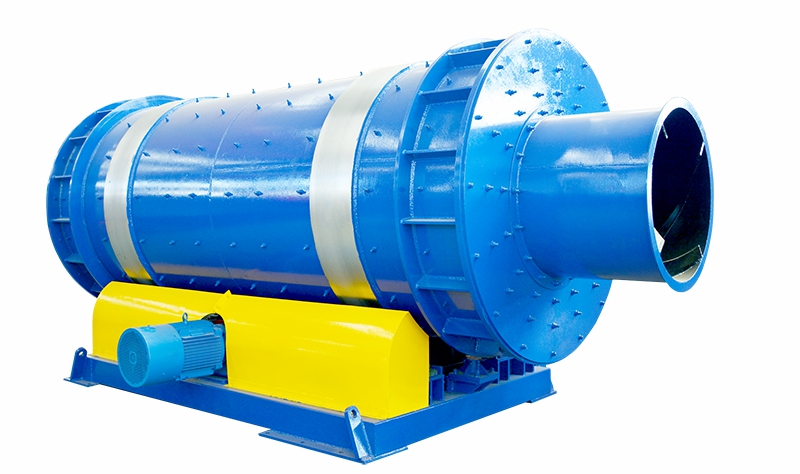

Tyre Drive Ball Mill Machine

【What’s the Tyre drive ball mill machine?】

The tyre drive ball mill also called Tire ball mill is mainly suitable for dry and wet grinding of power and mineral industries; Due to the use of tire drive, the ball mill lining board generally adopts rubber lining board with light weight, low noise and high wear resistance coefficient, and manganese steel lining board can also be used according to the actual situation. The grinding medium can be steel ball, ceramic grinding ball, steel rod or stone ball.

【Feature of Tyre drive ball mill machine】

1. Simple structure, no casting big gear ring, bearing and lubrication system, greatly reducing maintenance costs

2. The delivery time is short, the installation cost is low

3. Steel structure base is adopted, which is strong and durable

4. No ring gear, reduction gear, steel wheel or bearing

5. Ready made standard components, easy to replace and reduce downtime

6. Wear resistant truck tires, which can be easily purchased locally

7. Customizable discharge mode (overflow discharge or grid discharge)

8. All sections have quality inspection and testing, and trial run before leaving the factory

9. Rubber lifting plate, long service life, easy to replace

10. Convenient overhaul and maintenance

【Tyre drive ball mill Manufacture】As a tyre ball mill manufacturer, Our tyre driven ball mill can recommend manganese steel and rubber materials according to the actual abrasive needs of customers, the design of feeding and discharging end, the selection of electrical system and grinding medium. The preliminary engineer will provide the tire ball mill configuration suitable for the customer according to the customer’s site and needs

Tyre Drive Ball Mill Structure

【Tyre Drive Ball Mill Parts】The equipment is mainly composed of feeding device, inner linners, base frame, rotating tube body part, rubber tyre transmission device.

【Working Principle of Tyre Drive Ball Mill】The equipment slowly rotate it through the transmission device, and the materials to be grinded enter the mill through the feeding end of the mill. The grinding medium and materials are subjected to the friction and centrifugal force generated by the rotary motion of the barrel, and are brought to a certain height, and then are scattered and drained in the form of a curtain, and then the materials are hit and grinded by the grinding body. Due to the continuous feeding of materials, the materials in the cylinder move from the feeding end to the discharge end, and the materials reaching the particle size of finished products are discharged from the discharge end of the cylinder. During wet grinding, materials are carried out by water flow; During dry grinding, materials are forcibly discharged.

Tyre Drive Ball Mill Technical Parameter

Model | Shell rotation speed(r/min) | Ball load(t) | Feeding size(mm) | Discharging size(mm) | Capacity | Motor | Weight(t) |

(t/h) | |||||||

Φ900*1800 | 36-38 | 1.5 | <=20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 |

Φ900*3000 | 36 | 2.7 | <=20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

Φ1200*2400 | 36 | 3 | <=25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

Φ1200*3000 | 36 | 3.5 | <=25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

Φ1200*4500 | 32.4 | 5 | <=25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

Φ1500*3000 | 29.7 | 7.5 | <=25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

Φ1500*4500 | 27 | 11 | <=25 | 0.074-0.4 | 3-6 | 110 | 21 |

Φ1500*5700 | 28 | 12 | <=25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

Φ1830*3000 | 25.4 | 11 | <=25 | 0.074-0.4 | 4-10 | 130 | 28 |

Φ1830*4500 | 25.4 | 15 | <=25 | 0.074-0.4 | 4.5-12 | 155 | 32 |

Φ1830*6400 | 24.1 | 21 | <=25 | 0.074-0.4 | 6.5-15 | 210 | 34 |

Φ1830*7000 | 24.1 | 23 | <=25 | 0.074-0.4 | 7.5-17 | 245 | 36 |

Φ2100*3000 | 23.7 | 15 | <=25 | 0.074-0.4 | 6.5-36 | 155 | 34 |

Φ2100*4500 | 23.7 | 24 | <=25 | 0.074-0.4 | 8-43 | 245 | 42 |

Φ2100*7000 | 23.7 | 26 | <=25 | 0.074-0.4 | 8-48 | 280 | 50 |

Φ2200*4500 | 21.5 | 27 | <=25 | 0.074-0.4 | 9-45 | 280 | 48.5 |

Φ2200*6500 | 21.7 | 35 | <=25 | 0.074-0.4 | 14-26 | 380 | 52.8 |

Φ2200*7000 | 21.7 | 35 | <=25 | 0.074-0.4 | 15-28 | 380 | 54 |

Φ2200*7500 | 21.7 | 35 | <=25 | 0.074-0.4 | 15-30 | 380 | 56 |

Φ2400*3000 | 21 | 23 | <=25 | 0.074-0.4 | 7-50 | 245 | 54 |

Φ2400*4500 | 21 | 30 | <=25 | 0.074-0.4 | 8.5-60 | 320 | 65 |

Send us a message

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.