Raymond Mill Machine

【What’s the Raymond Mill Machine?】

Raymond mill is widely used for grinding mineral products and materials in metallurgy, building materials, chemical industry, mining and other fields. It is suitable for processing various nonflammable and explosive minerals with Mohs hardness below 7 and humidity below 6%, such as gypsum, talc, calcite, limestone, marble, potassium feldspar, barite, dolomite, granite, kaolin, bentonite, maifanite, bauxite, ferric oxide red, iron ore, etc, The fineness of the finished product is between 613 μ m and 44 μ m (0.613 mm – 0.044 mm). Through the joint action of the analyzer and the fan, the requirements of different users can be met. The mill is a high-efficiency closed circuit circulating pulverizing equipment. Compared with the ball mill, it has the advantages of high efficiency, low power consumption, small floor area, small capital investment and no environmental pollution.

【Feature of Raymond Mill Machine】

1. The raymond mill machine is a vertical structure, which occupies a small area and is highly systematic. It can form an independent production system from rough processing of raw materials to transportation to pulverizing and final packaging.

2. Compared with other milling equipment, the screening rate is up to 99%.

3. The transmission device of Raymond mill host adopts sealed gear box and pulley, which ensures stable transmission and reliable operation.

4. The important parts of Raymond mill are made of high-quality castings and profiles, with fine process and strict process, ensuring the durability of the whole equipment.

5. The electrical system adopts centralized control, and the grinding workshop can basically realize unmanned operation, and maintenance is convenient.

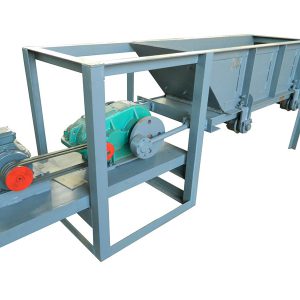

Raymond Mill Structure

【Raymond Mill Parts】The raymond mill machine is mainly composed of main mill machine, analyzer, fan, finished product cyclone separator, fine powder cyclone separator and air duct. The main machine is composed of frame, air inlet volute, blade, grinding roller, grinding ring and housing.

【Working Principle of Raymond Mill】During operation, the materials to be crushed are fed into the machine from the feed hopper at the side of the machine cover. The grinding roller device suspended on the plum blossom frame of the main machine rotates around the vertical axis, and at the same time rotates itself. Due to the centrifugal force during rotation, the grinding roller swings outward and presses against the grinding ring, enabling the blade to shovel the materials and send them between the grinding roller and the grinding ring. The purpose of crushing materials is achieved due to the rolling compaction of the grinding roller.

Raymond Mill Technical Parameter

Model | Mill Roller | Mill ring | Input size (mm) | Output size (mm) | Capacity (t/h) | Power | Weight (ton) | Size | |||

Qty | Diameter | Height | Inner dia | Height | |||||||

3R2615 | 3 | 260 | 150 | 780 | 150 | 20 | 0.2-0.044 | 0.5-2.7 | 18.5 | 4.2 | 5.2×3.4×5.9 |

3R2715 | 3 | 270 | 150 | 830 | 150 | 20 | 0.7 – -3.1 | 22. | 4.8 | 5.6×3.4×5.9 | |

4R3016 | 4 | 300 | 160 | 880 | 160 | 20 | 1.0-4.0 | 30. | 8.5 | 7.1×5.9×7.9 | |

4R3216 | 4 | 320 | 160 | 970 | 160. | 25 | 2.5-6.0 | 45 | 14 | 8.8×5.9×9.5 | |

5R4121 | 5 | 410. | 210 | 1280 | 210 | 30 | 5.0-11.0. | 75 | 31.8 | 9.2×7.2×9.7 | |

6R4528 | 6 | 450 | 280 | 1770 | 280 | 30 | 9.0-15.0. | 132 | 52.5 | 12.5x8x10.5 | |

Send us a message

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.