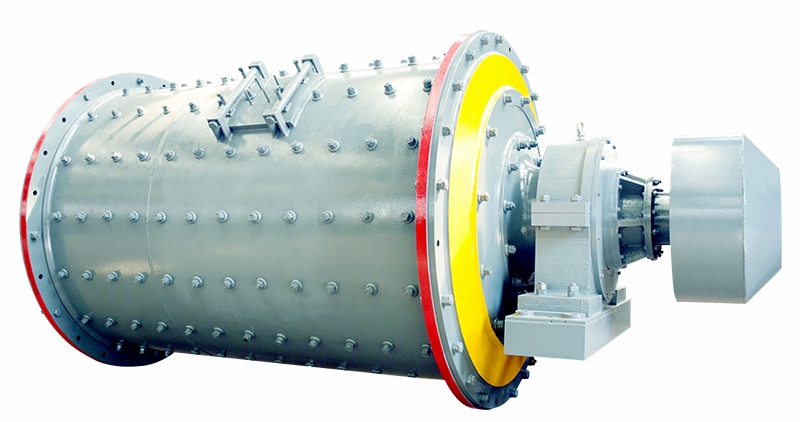

Grid Type Ball Mill Machine

【What’s the Grid type ball mill machine?】Grid type ball mill, its discharge mode is through the form of sieve plate. The overflow type has no sieve plate (the end lining plate is used, which is the same model as the grinding head). The Grid type ball mill can discharge qualified products in time and reduce the over crushing of ore. the grinding efficiency is high. The unit processing capacity is about 15% higher than that of the overflow ball mill of the same specification, and the ball loading capacity is large. When the particle size of the material needs to be grinded to 48 ~ 65 mesh uniform products, the Grid type ball mill is better.

【Feature of Grid type ball mill machine】

1. The hollow shaft of the Grid type ball mill is made of steel castings, the lining can be removed and replaced, the rotary gear is processed by casting hobbing, and the cylinder is inlaid with wear-resistant lining plate, which has good wear resistance.

2. The inner part of the Grid type ball mill cylinder is made of wear-resistant materials, so as to strengthen the wear resistance and prolong the service life; In addition, it can provide drum feeder and combined feeder to meet the requirements of different users.

3. The Grid type ball mill can store less pulp, so it can load more balls, and it is convenient to load small balls because of the barrier of the grid. When the steel ball falls, the impact effect weakened by the pulp resistance is also light, so the production efficiency is high.

【Grid type ball mill Manufacture】As a large well-known Grid ball mill manufacturer, you can enjoy the worry free after-sales guarantee when purchasing equipment in our company. You have a specially assigned person to be responsible for every step of production, and you have a specially assigned person to solve the late faults in time, so as to ensure the smooth and high-yield progress of your production.

Grid Type Ball Mill Structure

【Grid Type Ball Mill Parts】The equipment is mainly composed of six parts: barrel, ore feeder, ore ejector, transmission device, bearing and lubrication system, and the lattice plate of lattice ball mill has the function of “isolation”, the impact of medium ball will be significantly enhanced, and the crushing effect on materials will be stronger, which can achieve very high grinding effect.

【Working Principle of Grid type ball mill】The Grid type ball mill is a horizontal cylindrical rotating device, driven by gears, with two compartments and a lattice ball mill. The materials enter the first chamber of the mill evenly through the feeding hollow shaft screw from the feeding device. There are stepped liners or corrugated liners in this chamber, which are filled with steel balls of different specifications. The rotation of the cylinder generates centrifugal force to bring the steel balls to a certain height and then fall, which has a heavy impact and grinding effect on the materials. After rough grinding in the first bin, the materials enter the second bin through a single-layer partition plate. The bin is inlaid with a flat lining plate and a steel ball inside to further grind the materials. The powder is discharged through the discharge grate to complete the grinding operation.

Grid Type Ball Mill Technical Parameter

Model | rotation speed(r/min) | Ball load(t) | Feeding size(mm) | Discharging size(mm) | Capacity | Motor | Weight(t) |

(t/h) | |||||||

Φ900*1800 | 36-38 | 1.5 | <=20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 |

Φ900*3000 | 36 | 2.7 | <=20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

Φ1200*2400 | 36 | 3 | <=25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

Φ1200*3000 | 36 | 3.5 | <=25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

Φ1200*4500 | 32.4 | 5 | <=25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

Φ1500*3000 | 29.7 | 7.5 | <=25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

Φ1500*4500 | 27 | 11 | <=25 | 0.074-0.4 | 3-6 | 110 | 21 |

Φ1500*5700 | 28 | 12 | <=25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

Φ1830*3000 | 25.4 | 11 | <=25 | 0.074-0.4 | 4-10 | 130 | 28 |

Φ1830*4500 | 25.4 | 15 | <=25 | 0.074-0.4 | 4.5-12 | 155 | 32 |

Φ1830*6400 | 24.1 | 21 | <=25 | 0.074-0.4 | 6.5-15 | 210 | 34 |

Φ1830*7000 | 24.1 | 23 | <=25 | 0.074-0.4 | 7.5-17 | 245 | 36 |

Φ2100*3000 | 23.7 | 15 | <=25 | 0.074-0.4 | 6.5-36 | 155 | 34 |

Φ2100*4500 | 23.7 | 24 | <=25 | 0.074-0.4 | 8-43 | 245 | 42 |

Φ2100*7000 | 23.7 | 26 | <=25 | 0.074-0.4 | 8-48 | 280 | 50 |

Φ2200*4500 | 21.5 | 27 | <=25 | 0.074-0.4 | 9-45 | 280 | 48.5 |

Φ2200*6500 | 21.7 | 35 | <=25 | 0.074-0.4 | 14-26 | 380 | 52.8 |

Φ2200*7000 | 21.7 | 35 | <=25 | 0.074-0.4 | 15-28 | 380 | 54 |

Φ2200*7500 | 21.7 | 35 | <=25 | 0.074-0.4 | 15-30 | 380 | 56 |

Φ2400*3000 | 21 | 23 | <=25 | 0.074-0.4 | 7-50 | 245 | 54 |

Φ2400*4500 | 21 | 30 | <=25 | 0.074-0.4 | 8.5-60 | 320 | 65 |

Φ2700*4000 | 20.7 | 40 | <=25 | 0.074-0.4 | 12-80 | 400 | 94 |

Φ2700*4500 | 20.7 | 48 | <=25 | 0.074-0.4 | 12-90 | 430 | 102 |

Φ3200*4500 | 18 | 65 | <=25 | 0.074-0.4 | 20-90 | 800 | 137 |

Send us a message

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.