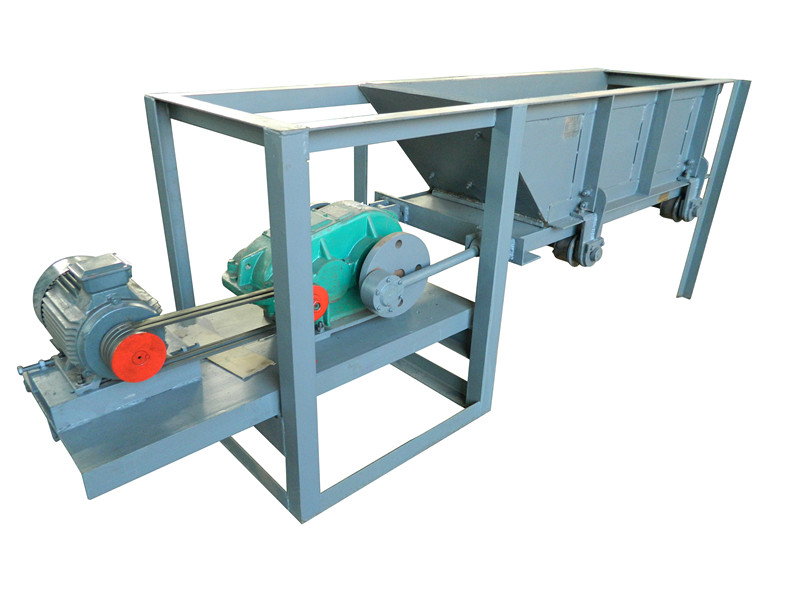

Chute Feeder Machine

【What’s the Chute feeder machine?】

The Chute feeder can be erected on the ground or hoisted on the discharge port of the ore bin. The bottom plate of the tank reciprocates, with a stroke of 20-60 times / min and a stroke of 20-200mm. The stroke can be properly adjusted by the eccentric of the driving device, and the eccentric distance is half of the stroke. According to the production practice of some concentrators, the eccentricity shall not be less than 30mm for viscous ores. The trough width of the chute feeder is about 2-2.5 times of the feeding particle size. Trough feeder can meet the feeding of iron ore with particle size less than 500mm. The commonly used specification is 980 * 1240 trough feeder, with a feeding particle size of 350-0mm, which is suitable for the feeding equipment of 400 * 600 jaw crusher.

【Feature of Chute Feeder】

1. Simple structure, uniform feeding, good continuous performance, adjustable excitation force;

2. The flow can be changed and controlled at any time, which is easy to operate and can adjust the ore feeding amount evenly;

3. The eccentric block is the excitation source, with low noise, low power consumption, good adjustment performance and no blanking phenomenon.

Spiral Classifier Structure

【Chute feeder Parts】The machine is mainly composed of rolling wheel shaft, movable chassis, frame, eccentric mechanism and transmission mechanism. The motor drives the worm gear reducer through the flexible coupling. The worm gear shaft of the worm gear reducer is equipped with a pair of eccentric mechanisms. The eccentric wheel drives the connecting rod and the connecting rod to drive the movable chassis to reciprocate to achieve uniform ore feeding.

【Working Principle of Chute Feeder】The chute feeder is generally installed at the lower part of the discharge opening of the bin. The ore falls onto the leakage plate at the bottom of the tank. The bottom leakage plate is set on the roller, and the leakage plate is connected to the reducer with double output shafts through the eccentric mechanism, and then connected to the motor through the coupling During operation, the motor drives the reducer through the coupling, and the eccentric plate reciprocates with the leakage plate between the groove frame bottom and the roller through the eccentric plate to complete uniform feeding.

Chute Feeder Technical Parameter

Specification | Capacity | Motor Power |

600×500 | 10.5-25.5 | 4 |

980×1240 | 36-90 | 7.5 |

1000×1900 | 300 | 7.5 |

Send us a message

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.