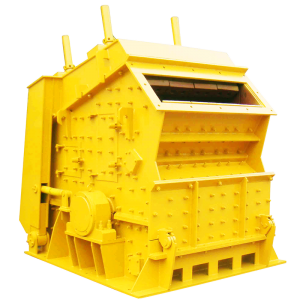

Compound Crusher

【What’s the Compound Crusher?】Vertical Compound crusher is developed from our product vertical compound crusher that has been listed in national mechanical industry standards. Vertical Compound crusher is also called a vertical crusher. As a kind of small rock crusher, it is suitable for crushing limestone, clinker, coal and other minerals in the building materials industry, mining, metallurgy, and chemical industry.

【Feature of Compound Crusher】Compound crusher has unique features of large production capacity, big crushing ratio, low energy consumption, good sealing effect, stable operation and easy maintenance.

【Compound Crusher Factory】As a typical kind of small stone crusher machine, compound crusher has an incomparable performance during its production process. Our engineers are here to offer you free consultation including compound crusher price, solution on machine selection and flow chart.

Compound Crusher Structure

【Compound Crusher Parts】feed hopper; machine cover; spindle; cylinder; upper rotor; lower rotor; chassis; base; pulley; lower hopper; tensioning device; two crushing cavities in the motor body – upper crushing cavity and lower crushing cavity. There are conical rotors in the upper crushing cavity and cylindrical rotors in the lower crushing cavity,etc.

【Working Principle of Compound Crusher】The massive ore falls into the upper throwing plate in the upper crushing chamber from the feed hopper. With the help of the centrifugal force of the throwing plate, the material is thrown to the inner wall of the cylinder and collides violently with the impact plate installed on the inner wall. At the same time, the materials collide with each other to break or produce a large number of hairline cracks. Then, after the material enters the conical rotor chamber, it falls in a spiral shape in the conical space. After stamping and extrusion, the cracked ore is further crushed. Due to the inclination between the conical rotor and the lining plate, the smaller materials are moved downward to achieve automatic grading crushing from large to small. The materials are hit by the hammer in the conical rotor cavity, and the high-speed running block collides with the impact plate again, and the material flow collides with each other, so that the materials are crushed through the impact, impact, shear and extrusion surface, so as to improve the crushing efficiency.

Compound Crusher Technical Parameter

Model | 800 | 1000 | 1250 | 1500 | 1750 |

Rotor Diameter | 650 | 800 | 1000 | 1250 | 1560 |

Cylinder Height(mm) | 800 | 850 | 850 | 1000 | 1410 |

Main Shaft Rotation Speed( r/min) | 1350 | 970 | 740 | 650 | 600 |

Feeding Size (mm) | 50 | 70 | 100 | 100 | 100 |

Discharging Size(mm) | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 |

Processing Capacity(m3/h) | 1-3 | 2-5 | 4-10 | 6-12 | 8-20 |

Power(kw) | 30 | 55 | 75 | 110 | 132 |

Motor Rotation Speed | 1440 | 1440 | 750 | 750 | 750 |

Dimensions (LxWxH)(mm) | 2200x860x1980 | 2700x1160x2000 | 2800x1400x2730 | 3350x2100x2800 | 3100x1900x2300 |

Total weight(t) | 2.3 | 4.5 | 9.73 | 18.1 | 26.61 |

Send us a message

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.