Flotation Machine

【What’s the Flotation machine?】

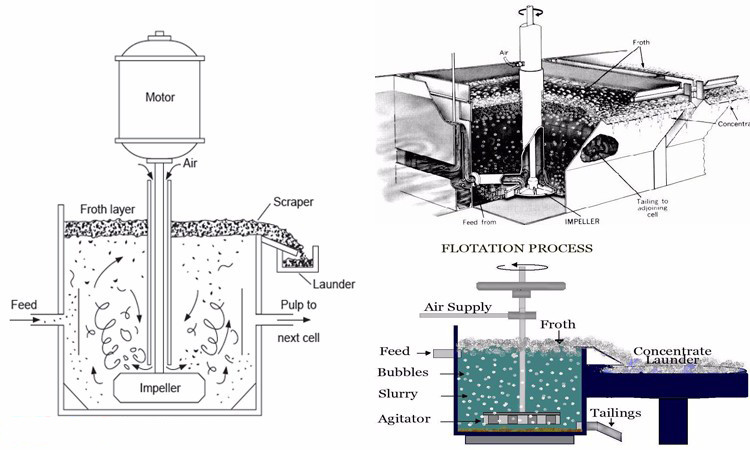

Flotation machine is the abbreviation of floating concentrator, which refers to the mechanical equipment that completes the flotation process. In the flotation machine, some ore particles are selectively fixed on the bubbles by stirring and aerating the slurry treated by adding reagents; The foam product is scraped out from the surface of the pulp and the rest is retained in the pulp to achieve the purpose of separating minerals. There are many structural forms of flotation machines, and the most commonly used is the mechanical agitation flotation machine.

【Feature of Flotation machine】

1. It can self absorb air and pulp, and it is easy to realize gravity flow when the middling returns,

2. Less auxiliary equipment, orderly equipment configuration, simple operation and maintenance, etc

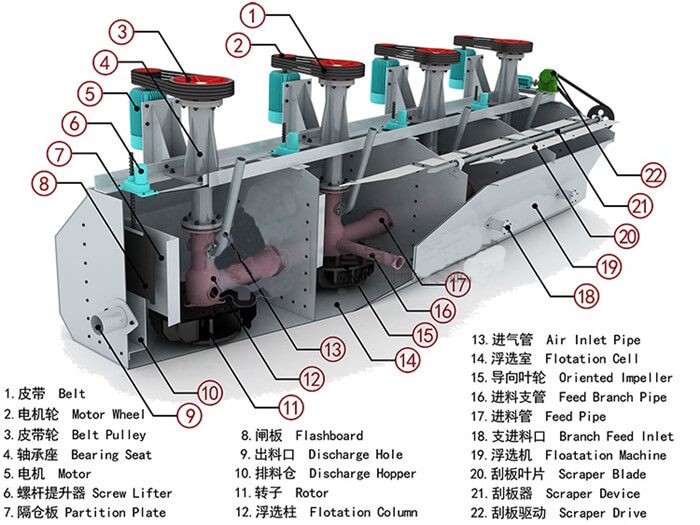

Flotation Machine Structure

【Flotation Machine Parts】It is mainly composed of impeller, cover plate, main shaft, central cylinder and groove body. The entire impeller structure is installed on the main beam of the tank body and driven by the motor through the V-belt. The structure feature of this machine is that the impeller is composed of closed double truncated cone, which can produce strong pulp circulation. The machine can also be equipped with automatic control device for pulp to adjust the liquid level.

【Working Principle of Flotation Machine】The impeller of the flotation machine is driven by the V-belt of the motor to rotate, generating centrifugal action to form negative pressure. On the one hand, it sucks enough air to mix with the pulp, on the other hand, it stirs the pulp to mix with the medicine, and at the same time, it refines the foam to make the minerals adhere to the foam and float to the pulp surface to form the mineralized foam. Adjust the height of the ram and control the liquid level so that the useful foam can be scraped out by the scraper.

Flotation Machine Technical Parameter

|

Category |

Specification |

Effective |

Processing |

Main shaft loam board |

Dimensions |

Single |

|||

|

Power(kw) |

Rotate Speed(r/min) |

Rotate Speed(r/min) |

Power(kw) |

||||||

|

XJK type |

XJK-0.35 |

0.35 |

0.18-0.4 |

1.5 |

483 |

25 |

1.1 |

0.7×0.7×0.7 |

0.5 |

|

XJK-0.62 |

0.62 |

0.3-0.9 |

3.0 |

400 |

25 |

1.1 |

0.90×0.82×0.85 |

1.0 |

|

|

XJK-1.1 |

1.1 |

0.6-1.6 |

5.5 |

330 |

25 |

1.1 |

1.1×1.1×1 |

1.4 |

|

|

XJK-2.8 |

2.8 |

1.5-3.5 |

11 |

280 |

25 |

1.1 |

1.75×1.6×1.1 |

2.5 |

|

|

XJK-5.8 |

5.8 |

5-7 |

22 |

240 |

25 |

1.5 |

2.2×2.2×1.2 |

3.6 |

|

|

SF type |

SF-0.37 |

0.37 |

0.2-0.4 |

1.5 |

386 |

25 |

1.1 |

0.7×0.7×0.75 |

0.5 |

|

SF-0.7 |

0.7 |

0.3-0.9 |

3 |

400 |

25 |

1.1 |

0.9×0.82×0.95 |

1.0 |

|

|

SF-1.2 |

1.2 |

0.6-1.6 |

5.5 |

330 |

25 |

1.1 |

1.1×1.1×1.1 |

1.9 |

|

|

SF-2.8 |

2.8 |

1.5-3.5 |

11 |

268 |

25 |

1.1 |

1.75×1.6×1.15 |

2.6 |

|

|

SF-4 |

4 |

2-4 |

15 |

220 |

25 |

1.5 |

1.85×2.05×1.2 |

2.9 |

|

|

SF-8 |

8 |

4-8 |

30 |

191 |

25 |

1.5 |

2.2×2.9×1.4 |

4.2 |

|

|

SF-10 |

10 |

5-10 |

30 |

191 |

25 |

1.5 |

2.2×2.9×1.7 |

4.5 |

|

|

SF-20 |

20 |

5-20 |

30×2 |

191 |

25 |

1.5 |

2.85×3.8×2 |

9.9 |

|

|

JJF type |

JJF-2 |

2 |

1-3 |

7.5 |

443 |

25 |

1.5 |

1.4×1.4×1.1 |

1.7 |

|

JJF-4 |

4 |

2-4 |

11 |

305 |

25 |

1.5 |

1.6×2.15×1.25 |

2.4 |

|

|

JJF-8 |

8 |

4-8 |

22 |

233 |

25 |

1.5 |

2.2×2.9×1.4 |

4.5 |

|

|

JJF-10 |

10 |

5-10 |

22 |

233 |

25 |

1.5 |

2.2×2.9×1.7 |

4.9 |

|

|

JJF-16 |

16 |

5-16 |

30 |

180 |

25 |

1.5 |

2.85×3.8×1.7 |

8.0 |

|

|

JJF-20 |

20 |

5-20 |

37 |

180 |

25 |

1.5 |

2.9×3.8×2.0 |

10.5 | |

Send us a message

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.