Single Stage Hammer Crusher

【What’s the Single Stage Hammer Crusher?】Single-stage crusher is also called single-stage crushing machine or single-stage breaker. Single-stage crusher is suitable for crushing brittle materials with compressive strength less than 150MPa, such as limestone, shale, gypsum, coal, shale and siltstone and limestone and clay mixture. Single-stage crusher can crush the giant materials to the size that grinding needs. Thereby, it took the place of the traditional two-stage crushing to simplify processes and reduce production costs.

【Feature of Single stage Hammer Crusher】Single stage Hammer crusher has unique features of large production capacity, big crushing ratio, low energy consumption, good sealing effect, stable operation and easy maintenance.

【Single Stage Hammer Crusher Manufacture】Our single stage hammer crusher has an incomparable performance during its production process. Our engineers are here to offer you free consultation including compound crusher price, solution on machine selection and flow chart.

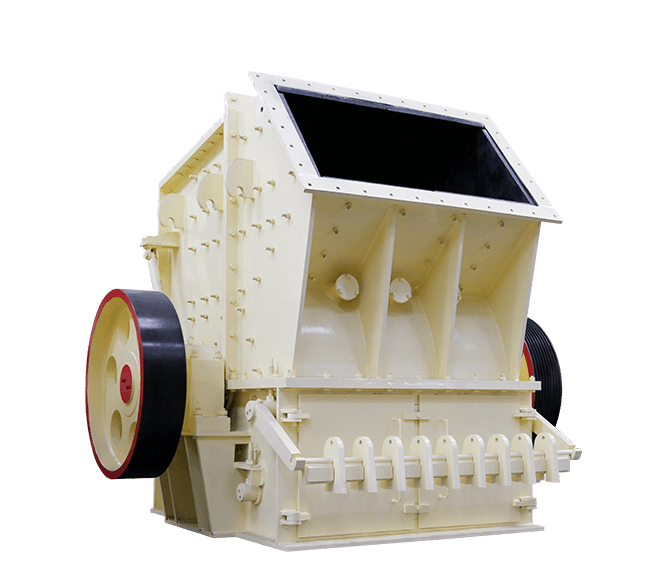

Single Stage Hammer Crusher Structure

【Single stage Hammer Crusher Parts】The structure of single-stage hammer crusher mainly includes crusher rotor, crusher shell, crusher plate, discharge grate, iron gate (safety device) and drive part, etc

【Working Principle of Single stage Hammer Crusher】The single-stage hammer crusher mainly breaks the ore through the strong impact of the hammer head on the ore in the upper cavity and the impact of the ore on the impact lining plate. The main motor drives the rotor equipped with a large belt pulley through the combined belt. The ore is fed into the feeding port of the crusher by the heavy feeding equipment. The ore larger than the gap between the shed bars is struck by the high-speed rotating hammer at a higher linear speed. At the same time, the ore is crushed or thrown up. The thrown up ore impacts the impact lining plate or collides with each other and is crushed again until it is smaller than the size of the grate joint, and is discharged from the lower part of the chamber.

Single Stage Hammer Crusher Technical Parameter

MODEL | ROTOR SIZE | ROTOR LENGTH | HAMMER | MAX. FEED SIZE | INLET SIZE | POWER | DIMENSION | CAPACITY |

DPX15 | 800 | 650 | 12 | ≤500 | 570X630 | 45 | 1615×1662×1636 | 15-35 |

DPX35 | 1000 | 1030 | 24 | ≤700 | 1050X760 | 75 | 2016×2260×2330 | 30-40 |

DPX65 | 1200 | 1290 | 24 | ≤800 | 1320X760 | 132 | 2316×2520×2633 | 40-60 |

DPX90 | 1400 | 1300 | 30 | ≤900 | 1330X960 | 200 | 2654×2871×3060 | 90-125 |

DPX125 | 1700 | 35 | 1990X960 | 250 | 2654×3391×3060 | 125 | ||

DPX150 | 1600 | 1560 | 30 | ≤1100 | 1520X1120 | 280 | 3427×3460×3640 | 130-180 |

DPX180 | 2020 | 40 | 2050X1200 | 355 | 3427×3920×3640 | 160-200 | ||

DPX250 | 1800 | 2000 | 42 | ≤1300 | 2180X1320 | 630 | 9050×6600×4335 | 250-400 |

DPX300 | 2000 | 2200 | 40 | 2440X1320 | 800 | 9650×7200×4735 | 450-650 |

Send us a message

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.