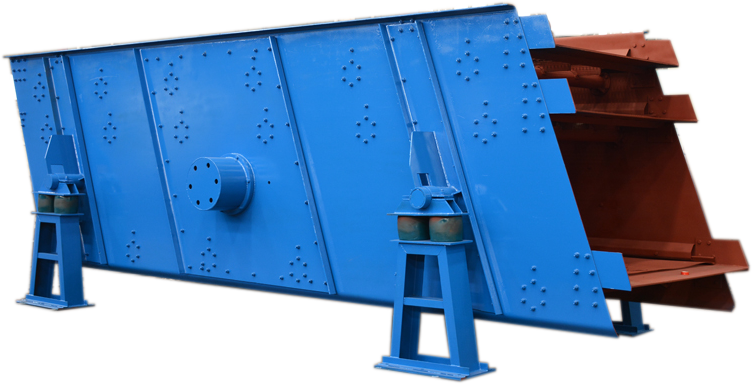

Vibrating Screen Machine

【What’s the Vibrating Screen machine?】

Vibrating screen is mainly used for the screening and classification of powder and granular materials. Using the vibration motor as the vibration source, the materials are thrown up on the screen and move forward in a straight line. The material is evenly distributed from the feeder. Entering the feed port of the sieving machine, a variety of screen tops and sieves are generated through the multi-layer screen, and they are discharged from their respective outlets. It has the characteristics of low energy consumption, high output, simple structure, convenient maintenance, fully enclosed structure, no dust overflow, automatic unloading, etc., which is more suitable for assembly line operation.

【Feature of Vibrating Screen】

1.Use the unique eccentric structure to produce powerful vibrating force.

2.The beam and case of screen are connected with high strength bolts without welding.

3.Simple structure and easy maintenance.

4.Adopting tire coupling and soft connection makes operation smooth.

5.High screen efficiency, great capacity and longer service life.

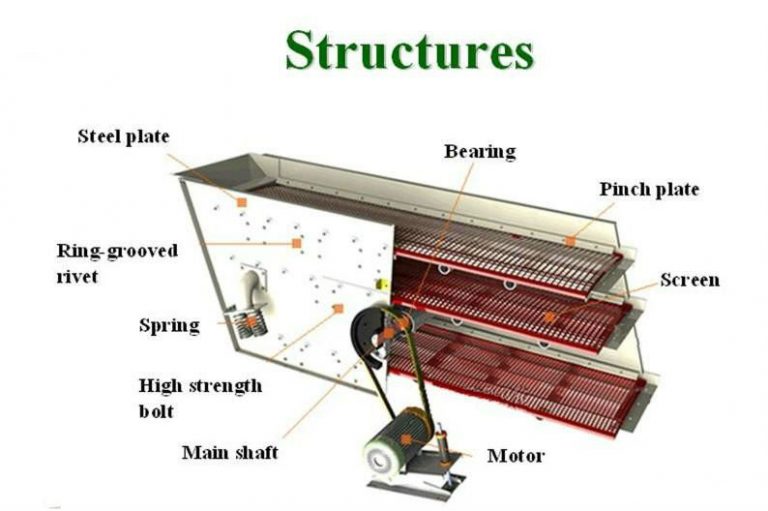

Vibrating Screen Structure

【Vibrating Screen Parts】The structure of vibrating screen is mainly composed of machine base, vibrating motor, vibrating body, screen frame and other components, and then the vibrating motor is used as the vibration source to make the screen box vibrate for screening.

【Working Principle of Vibrating Screen】When the two vibrating motors installed on the screen body in the longitudinal direction operate relatively, the transverse exciting force generated by the two vibrating motors counteracts each other due to the relative operation of the motors. The longitudinal exciting force is transmitted to the whole screen box through the vibrating body to vibrate the screen surface, so that the materials on the screen surface will jump on the screen surface in the direction of discharging products by the exciting force, and the materials smaller than the screen holes will fall to the lower layer through the screen holes, After continuous hopping, it flows out from the outlet. Due to the reasonable screening process, the materials can be classified by vibrating screen, and several materials with different particle sizes can be obtained to complete the classification of materials.

Vibrating Screen Technical Parameter

Model | Screen area (m²) | Power (kw) | Capacity (t/h) | Feed size (mm) | Weight (kg) | Overall dimension (mm) |

ZSD1230 | 3.6 | 1.9 | 30-80 | ≤10 | 1260 | 3085*1590*1439 |

ZSD1236 | 4.32 | 2.2 | 30-80 | ≤10 | 1600 | 3677*1590*1600 |

ZSD1530 | 4.5 | 2.2 | 80-120 | ≤10 | 1845 | 3075*2491*1601 |

ZSD1536 | 5.4 | 3 | 80-120 | ≤10 | 2000 | 3200*2491*1802 |

ZSD1836 | 6.48 | 7.5 | 100-140 | ≤10 | 3569 | 3758*3075*1988 |

ZSD1842 | 7.56 | 7.5 | 100-140 | ≤10 | 3914 | 4368*3075*2000 |

ZSD1848 | 8.64 | 7.5 | 100-140 | ≤10 | 3967 | 4791*3065*1959 |

ZSD2242 | 10.1 | 11 | 140-180 | ≤10 | 4855 | 4403*3737*1931 |

ZSD2448 | 11.52 | 11 | 140-180 | ≤10 | 5068 | 5008*3737*1977 |

ZSD3048 | 14.4 | 15 | 200-250 | ≤10 | 7550 | 4959*4518*2218 |

Send us a message

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours. Rest assured that we won’t reveal your information to anyone.